OUR MISSION

Excell Solutions makes local companies more competitive through our unparalleled support of product development and manufacturing processes. Formed from the marriage of a local machine shop and sheet metal shop, we are fully equipped on both fronts to provide high precision parts, fast. Our Job is to make your problems go away. You tell us what you need and when you need it and we will work to your schedule. Not the other way around!

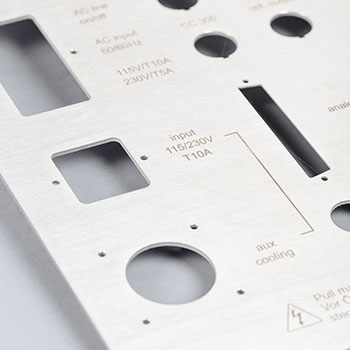

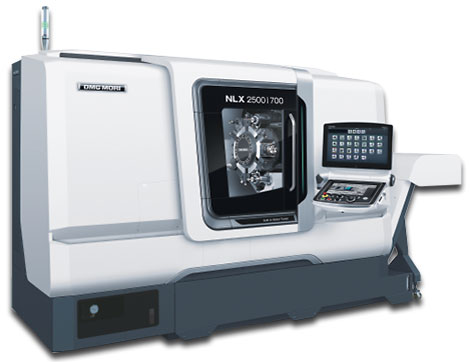

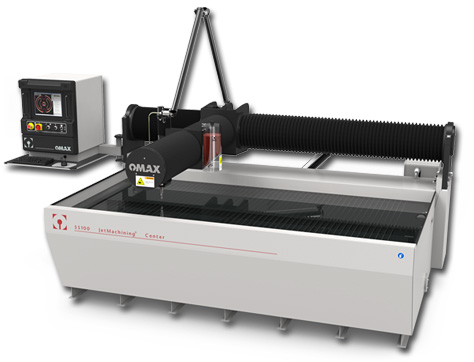

One Stop Shopping for all Precision Sheet metal, Precision Machining and Fabrication Needs

Low to Mid- Size Volume Orders

40 employees

50,000 Square Foot Facility

13 Years of Business

Explore a Sample of Our Capabilities